Solutrans 2023: Kögel with French specialties and trailers for multimodal transport

Kögel is expanding its product range at the Solutrans trade fair to include a version of the Kögel Cargo with a specially reinforced floor that has been specially adapted to the needs of French customers. The Burtenbach-based vehicle manufacturer is also presenting the Kögel Port with the particularly convenient and safe Multi Container Stop container locking system. In addition, Kögel experts will explain why trailers from Kögel enable a favorable CO2 footprint and what advantages the in-house value-added services offer.

A version of the Kögel Cargo specially adapted to the needs of French customers is celebrating its premiere at Solutrans. This has a particularly robust wooden floor that also withstands especially high mechanical loads and noticeably reduces the resulting wear and tear on the trailer. Omega-shaped steel profiles are inserted between the individual wooden segments in the longitudinal direction of the trailer. If damaged, the wooden planks can be replaced individually. In addition, the omega profile floor offers an even higher forklift axle pressure of 8.0 instead of 7.2 tons. This means that even a heavy forklift truck - as is customary in France - can drive from the rear into the trailer to load it, but without putting undue strain on it.

Multi Container Stop: uniquely safe and convenient

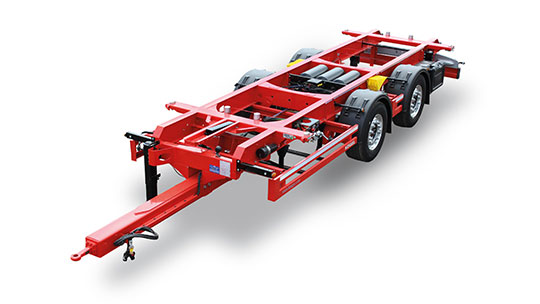

Kögel is also presenting the Kögel Multi Container Stop (MCS). The innovative, particularly convenient and safe container locking system revolutionizes the transport of swap bodies of all designs on the road. The MCS eliminates the need for conventional container locks, the so-called twist locks, at the front of the swap body. Here, the load is secured exclusively via positive locking, which is demonstrably the best form of load securing in accordance with DIN EN 12642.

In contrast to the container latches widely used on the market, the Kögel MCS can be used in a self-explanatory manner. Operating errors are ruled out, as the front stop no longer needs to be operated at all. High-cube containers automatically strike the front of the cross beam when they are placed on the ground and are thus secured by positive locking in accordance with the standards. The tunnel in the container secures the load to the side. ISO containers without a tunnel are secured by a pin on the top of the MCS, which absorbs the forces in the direction of travel and laterally to the direction of travel.

Secure container in half the time

There is no need to adjust the front mounts, plug-in bolts or stops on the front of the container chassis to secure the different container types. Operating the conventional twist locks is also strenuous work for the driver due to their heavy weight. On top of that, handling the side extensions, swivel arms and other components costs a lot of time. With the Kögel MCS, this is no longer necessary in this form. The possibilities for operating errors and injuries are also reduced.

The latches at the rear are designed as usual. They take over load securing against the direction of travel and help to absorb the forces occurring laterally. The combination of Kögel MCS at the front and conventional locking devices at the rear of the chassis means that the driver needs at most half the time to secure the swap body.

Multimodal transport becomes more attractive thanks to Kögel

With the MCS, Kögel facilitates the transport of swap bodies and increases the attractiveness of environmentally friendly multimodal transport. The system is available for all container chassis of the current technological generation, for the Combi trailer series and for all platform vehicles from Kögel. At Solutrans, Kögel will be demonstrating the Multi Container Stop on a Port 45 Simplex container chassis with rear extension for ISO and highcube containers of sizes 20 to 45 feet.

All Kögel Port models are also based on the latest chassis generation. Likewise, all container chassis with front extension now have Kögel's own lightweight and low-maintenance front extension. As a result of the changeover, they weigh significantly less. The weight advantage over the previous versions is up to 700 kilograms in basic equipment.

Lightweight construction is the key to greater sustainability

Intelligent lightweight construction, as practiced by Kögel, is a key technology that enables greater sustainability and a favorable CO2 footprint in transport, while at the same time offering economic benefits to the vehicle operator - just as Kögel promises with its slogan 'Economy meets Ecology'. This is because the extra payload either results in a lower CO2 footprint per transported ton or reduces the fuel consumption of the tractor unit if the payload is not fully utilized. Due to their low dead weight, all Kögel trailers and especially the special lightweight vehicles of the Kögel Light series offerplus on the road therefore not only have more payload, but they also save diesel and thus reduce the CO2 footprint.

Thanks to Kögel's clever modular system, customers can also use the Kögel Lightplus with various superstructures and in numerous industry designs. This means that the lightweight trailer can also be used in a wide range of transport sectors. Despite the payload advantage of around half a ton compared to the Kögel Cargo models, which are already lightweight in the industry environment, it offers the reliability and solidity you have come to expect from all Kögel models.

Rail-loadable and up to one ton lighter

This also applies to the Kögel Lightplus Rail, the first rail-loadable trailer in lightweight design. The vehicle offers a weight advantage of up to one ton compared to comparable standard designs and thus combines the economic and ecological advantages of lightweight vehicles with the use of the environmentally friendly rail mode of transport. In its basic configuration, the Kögel Light weighsplus Rail weighs only 6,060 kilograms, 300 kilograms less than the conventional Kögel Cargo Rail version. With the help of optionally available lightweight components, the tare weight of the Lightplus Rail to press up to 5,750 kilograms.

This is an outstanding value, because rail-loadable trailers are usually significantly heavier than road-only versions. However, the higher tare weight reduces the payload of the trailer. It is true that there are exceptions for vehicles in combined transport, which allow the permissible gross train weight to be increased to 44 tons between the loading and unloading point and the nearest suitable station to compensate for this disadvantage. However, this measure does not compensate for the increased fuel consumption of the tractor unit on the road caused by the extra weight.

Already in basic equipment suitable for common pocket wagons

Despite the lightweight design, however, customers need not fear any restrictions in the vehicle's operational capability or handling. The trailer has no disadvantages compared with conventional rail designs. Even in its basic configuration, the vehicle is suitable for use in the common pocket wagon types. Thanks to Kögel's modular system, customers can also choose from all the equipment variants of the Cargo Rail for the Lightplus Rail are available. These include industry solutions with paper equipment or stanchion pockets for steel transport as well as double codification with FlexiUse superstructure.

Value-added services from Kögel enable full cost control

Kögel will also be presenting its range of value-added services in Lyon. They provide customers with full cost certainty during the usage phase of a Kögel trailer. A key component of this is the Kögel Telematics trailer telematics system. Operating contracts tailored to the respective application allow a particularly attractive cost-benefit ratio. With status reports, analysis tools and the possibility of integrating them into all existing portals, the in-house telematics contributes to optimum vehicle condition and thus to the best possible operating costs. The use of Kögel Telematics in turn forms the basis for full-service contracts from Kögel. These form the all-round carefree package for all new trailers. Thanks to favorable monthly rates, haulage companies keep the costs of the vehicle under control.

The range of services offered by the Kögel After Market division also benefits from digitalization. Customers can identify and order spare parts 24/7 via the Kögel Parts Shop and pay for them using standard online systems. The range also includes Kögel Original Parts, spare parts in OEM quality at an attractive price-performance ratio, which help Kögel trailers maintain their performance and favorable operating costs over the long term.

Your point of contact for this press release:

Maximilian Franz

Head of Marketing & Public Relations

Tel. +49 82 85 88 – 12318

Maximilian.Franz@koegel.com

Download picture JPG | RGB | 72 DPI

Download picture JPG | RGB | 72 DPI